Revolutionize Manufacturing: Boost Productivity with Automated Riveting Machines

Topbest supply professional and honest service.

Google Hot Topics: Can Revolutionizing Manufacturing Boost Productivity with Automated Riveting Machines?

Revolutionize Manufacturing: Boost Productivity with Automated Riveting Machines.

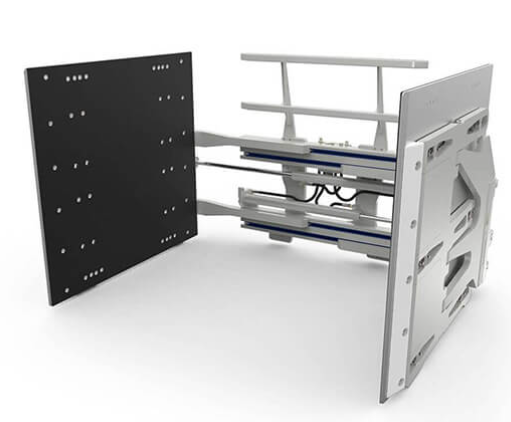

In today's rapidly changing industrial landscape, manufacturers are constantly seeking innovative ways to enhance productivity and streamline their production processes. One such breakthrough that is gaining significant traction is the use of automated riveting machines to revolutionize the manufacturing sector. By automating the riveting process, manufacturers can increase productivity, save costs, and improve overall efficiency. Can this paradigm shift truly revolutionize manufacturing and boost productivity? Let's delve deeper and explore the potential benefits of integrating automated riveting machines into the manufacturing process.

1. Improved Efficiency and Precision:

Automated riveting machines leverage sophisticated technology to optimize the riveting process. These machines are designed to accurately position rivets, apply optimal pressure, and ensure consistent results, thereby eliminating the variability associated with manual riveting. By streamlining and automating this critical process, manufacturers can enhance their efficiency, reduce errors, and achieve higher precision in their production.

2. Increased Productivity:

One of the primary benefits of adopting automated riveting machines is the significant boost in productivity they offer. These machines can perform riveting at a much faster pace compared to manual labor, increasing the output and reducing production time. With higher productivity, manufacturers can meet increasing customer demands, take on more orders, and scale their operations effectively.

3. Cost Savings:

Related links:Do you really need a welding table?

Can I Use an Almond Grinder for Other Nuts? Exploring the Versatility of Nut Grinders

How does a golf ball making machine work?

Can a Laser Cutter Effectively Cut Sheet Metal?

How to choose a fiber laser tube cutting machine

What factors should I consider when choosing the best oil press machine?

Advantages of AIR Plasma Cutting Machines

Integrating automated riveting machines can also result in substantial cost savings for manufacturers. While the initial investment may seem significant, the long-term benefits outweigh the upfront costs. Automated machines minimize labor requirements, eliminating the need for extensive manual workforces, which can be expensive. Additionally, these machines require minimal maintenance, reducing downtime and associated costs. Over time, these savings can lead to improved profitability for manufacturers.

4. Enhanced Workplace Safety:

Manual riveting processes typically involve repetitive motions and can pose ergonomic risks to workers. The use of automated riveting machines can significantly reduce these risks by replacing manual labor with mechanized operations. This shift not only enhances workplace safety but also reduces the likelihood of work-related injuries. The improved safety measures can lead to a better work environment and increased employee satisfaction.

5. Scalability and Adaptability:

Automated riveting machines are designed to be highly adaptable and scalable, allowing manufacturers to cater to varying production needs. These machines can be easily reprogrammed for different riveting requirements, enabling manufacturers to seamlessly switch between different product lines or adapt to evolving market demands. This flexibility empowers manufacturers to stay competitive and responsive in a dynamic market, opening up opportunities for growth and expansion.

The keyword "Revolutionize Manufacturing: Boost Productivity with Automated Riveting Machines" signifies the potential of automated riveting machines in transforming the manufacturing sector. This innovation has the power to revolutionize the industry by improving efficiency, increasing productivity, reducing costs, enhancing workplace safety, and providing scalability. By embracing this technology, manufacturers can stay ahead of the curve and ensure their operations are optimized for success.

In conclusion, the use of automated riveting machines unquestionably holds the key to revolutionizing manufacturing and boosting productivity. These machines not only offer enhanced efficiency and precision but also drive significant cost savings, improve workplace safety, and provide the flexibility needed for businesses to thrive. As manufacturers strive to remain competitive in an ever-changing landscape, it is imperative to explore the potential of automated riveting machines and embrace their transformative power. Will you join the revolution and propel your manufacturing process into the future?

For more information, please visit our website.

Contact us to discuss your requirements of Hotmelt Glue Dispensing Machine. Our experienced sales team can help you identify the options that best suit your needs.

Related links:Benefits of Having Automated Adhesive Dispensing Systems

What is a Gold Melting Furnace

Leveraging Fiber Laser Machines in the Aerospace Industry

What is a Turret CNC Lathe?

What is a Mobile Stone Crushing Plant?

What is the cost of automatic EPS shape molding machine?

How does a sand making machine work?