6 Tips To Get The Most Out of Your Conveyor Belt

Conveyor belts are crucial components in various industries, facilitating the efficient movement of materials and products. To ensure optimal performance and longevity of your conveyor belt, it's essential to take proper care and maintenance measures. Here are six tips to help you get the most out of your conveyor belt:

1. Regular Inspection and Maintenance: Perform routine inspections of your conveyor belt system to identify any signs of wear, damage, or misalignment. Check for worn-out parts, frayed edges, and belt tension issues. Address any problems promptly to prevent further damage and ensure smooth operation. Regular maintenance tasks, such as cleaning, lubricating moving parts, and tightening bolts, should be part of your maintenance routine.

2. Proper Training for Operators: Ensure that your conveyor rubber belt operators are adequately trained in operating the system safely and efficiently. Proper training can minimize operator errors, reduce the risk of accidents, and help extend the life of the conveyor belt.

3. Monitor Belt Tracking: Proper belt tracking is crucial for smooth and efficient operation. Misaligned belts can lead to premature wear, increased energy consumption, and potential damage to the conveyor system. Regularly check and adjust the belt tracking to keep it centered and aligned on the pulleys.

4. Control Material Load and Speed: Avoid overloading the conveyor belt beyond its capacity. Excessive loads can cause strain on the system and lead to premature wear and tear. Additionally, avoid abrupt changes in speed, as it can put undue stress on the belt and affect its longevity.

Related links:10 Best Tips for Buying Hastelloy Wire?

What are the specifications for a dust collector filter bag?

Is graphite smelting crucible worth the price?

Revolutionize Your Greenhouse with Space Frame Structures: FAQs Answered

What are the properties of neodymium magnets?

Unlocking the Truth About Rods Bod: FAQs Answered

What is super duplex pipe?

5. Protect Against Contamination: Protect your conveyor belt from contamination by foreign objects or materials that can cause damage. Implement appropriate guarding and covers to prevent debris, dust, or foreign objects from getting trapped in the system. Regularly clean the belt to remove any debris or spilled materials that could cause damage.

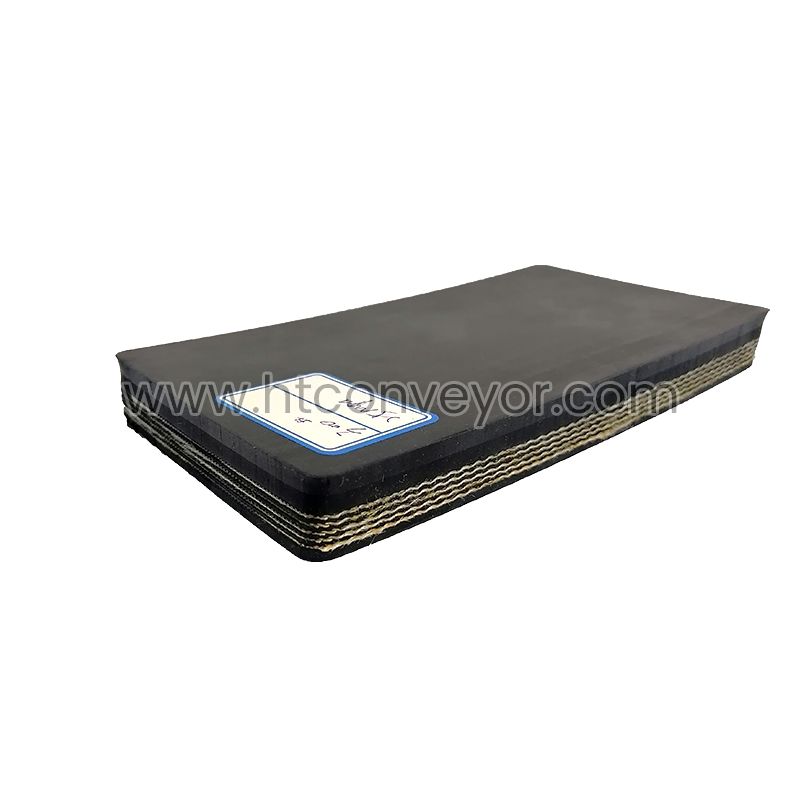

6. Choose the Right Conveyor Belt: Select a conveyor belt that is appropriate for the specific application and material handling needs. Consider factors such as the material type, weight, and temperature conditions. Using the right type of conveyor belt ensures optimal performance and minimizes wear and tear.

Bonus Tip: Invest in Spare Parts and Maintenance Tools: Keep essential spare parts on hand to minimize downtime in case of a breakdown. Having spare belts, rollers, and other critical components readily available can expedite repairs and keep your conveyor system operational. Additionally, invest in maintenance tools, such as belt trackers and tension gauges, to make routine maintenance tasks more efficient.

By following these tips and implementing a proactive maintenance approach, you can maximize the efficiency and lifespan of your conveyor belt system. Regular inspections, proper training, monitoring belt tracking, controlling material load and speed, protecting against contamination, and choosing the right conveyor belt are all crucial steps in getting the most out of your conveyor belt and ensuring a smooth and reliable material handling process.

Ultimate Guide to Stainless Steel Welded Mesh Panels: Benefits, Uses & Installation Tips

Baosteel Revolutionizes Can Making Industry with Innovation

What is the most pure metal?

Personalize your graphite block for B2B success?

Galvanized vs Galvalume: Which Metal Roofing Option is Best for You?

Top Picks: Graphite Electrodes Available at Sale

Best tips for selecting Carbide Rod With Coolant Hole?