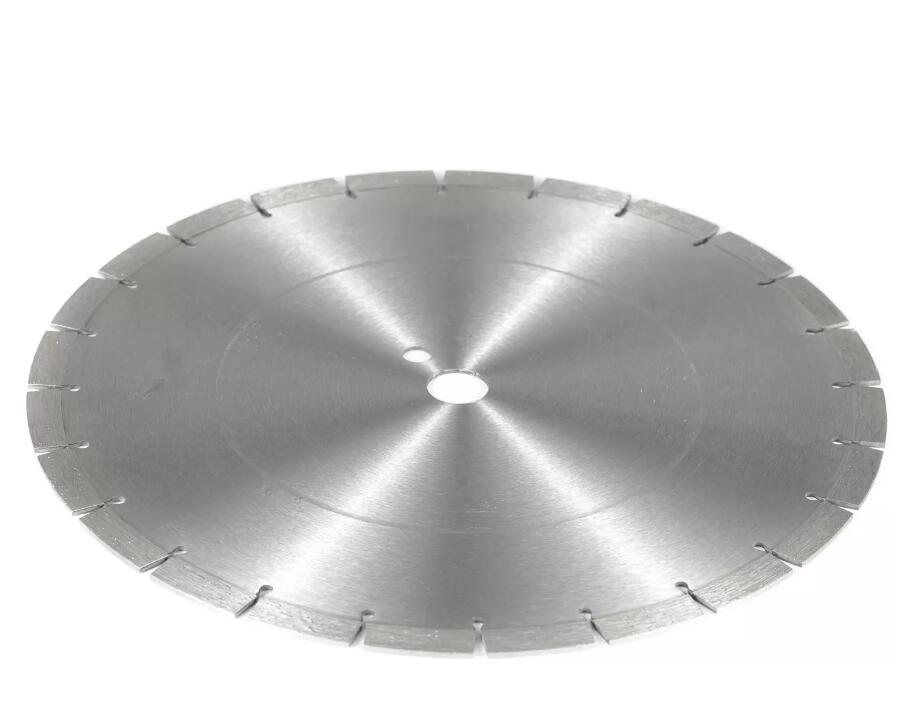

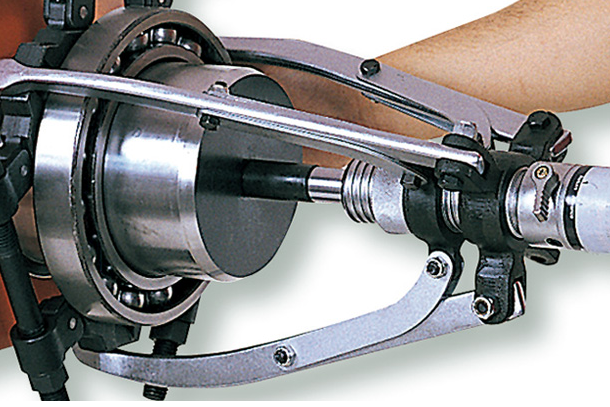

Durable Steel Body PDC Bits: Ultimate Abrasion Resistance.

Durable Steel Body PDC Bits: Ultimate Abrasion Resistance.

When it comes to drilling through tough formations, one crucial factor is the durability and wear resistance of the drilling bit. Enter steel body Polycrystalline Diamond Compact (PDC) bits, renowned for their exceptional durability and ultimate abrasion resistance. These bits are specifically designed to withstand the harshest drilling environments and provide optimum drilling performance.

The durability of steel body PDC bits is attributed to the use of high-grade steel material in their construction. This robust material ensures the bits can withstand heavy loads, high temperatures, and harsh drilling conditions without succumbing to excessive wear and tear. Additionally, the steel body provides excellent stability and rigidity to the bit, minimizing the chances of breakage or failure during drilling operations.

The exceptional wear resistance of steel body PDC bits is primarily due to the presence of Polycrystalline Diamond Compact cutters. These cutters are made from a composite material consisting of carefully synthesized diamond crystals and a cemented tungsten carbide substrate. This unique combination results in a highly durable cutter with exceptional hardness and wear resistance.

Related links:Top Non-Sparking Socket Driver Extension Bars 2021

Revolutionizing Appliances: The Ultimate Bending Machine Guide

Best practices for efficient fire extinguisher filling process?

Revolutionizing the industry: Are automatic sheet metal bending machines the future of manufacturing?

How does a booster system work?

How do non sparking tools work?

How does a sheet metal bending machine work?

During the drilling process, the PDC cutters come into direct contact with the rocks or formations being drilled. The hardness of the diamond crystals allows the cutters to effectively shear through the formation, while their wear resistance ensures minimal wear and tear even in highly abrasive formations. This ensures consistent and efficient drilling performance, saving both time and resources.

The durability and wear resistance of steel body PDC bits have significant implications for drilling operations. Firstly, the longevity of these bits reduces the frequency of bit changes, leading to substantial cost savings. Additionally, the ability to drill through tough formations without compromising performance ensures faster drilling rates and increased productivity.

Moreover, the ultimate abrasion resistance offered by steel body PDC bits minimizes the downtime associated with bit replacements. This translates to increased operational efficiency, reduced non-productive time, and enhanced overall drilling performance.

In conclusion, durable steel body PDC bits with ultimate abrasion resistance are essential for efficient drilling in challenging environments. The use of high-grade steel material and Polycrystalline Diamond Compact cutters ensures exceptional durability and wear resistance for reliable and high-performance drilling operations. With significant cost savings, increased productivity, and enhanced operational efficiency, these bits have revolutionized the drilling industry and continue to play a vital role in meeting the demands of modern drilling applications.

Please visit our website for more information on this topic.

The company is the world’s best Downhole Motor Manufacturer supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

Related links:The Ultimate Guide to Revitalizing Your Suncen

Why Beryllium Copper Linesman Pliers are Essential?

Revolutionize Your DIY Projects: Boost Air Compressor" - Have you discovered the game-changing benefits?

How do I choose the right circular saw blade for my project?

The Rise of Synthetic Fiber Brushes: A Revolution in Painting

Enhancing Surfaces with Wood Graining Tools: A Masterstroke of Artistry

The Non-Sparking Hammer: Ensuring Safety in Hazardous Environments