Electric Scissor Lifts: Elevating Efficiency and Safety

In the world of construction, maintenance, and warehouse operations, efficiency and safety are paramount. When the need arises to access high places, whether for repairs, installations, or material handling, electric scissor lifts have become a reliable and indispensable solution. These versatile machines are designed to elevate both workers and materials to varying heights while offering numerous advantages in terms of safety and convenience.

Understanding Electric Scissor Lifts

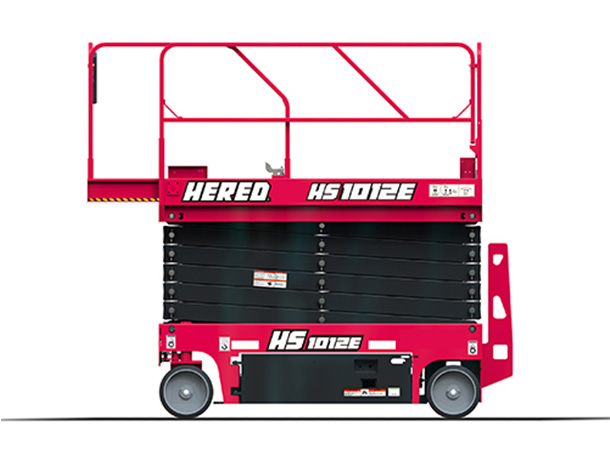

Electric scissor lifts are hydraulic-powered machines designed for vertical elevation. They consist of a platform, a base, and a set of crossed metal supports, resembling a scissor mechanism, which gives these lifts their name. The platform is where workers stand, and it can also carry materials or equipment, making them essential for a wide range of industries.

Key Features and Advantages

Versatility: Electric scissor lifts are incredibly versatile and can be used both indoors and outdoors. Their robust construction enables them to work on a variety of terrains, from smooth warehouse floors to uneven construction sites.

Quiet and Environmentally Friendly: Electric scissor lifts are known for their quiet operation. They produce minimal noise and no emissions, making them an environmentally friendly choice. This feature is particularly important for indoor applications and construction sites near residential areas.

Safety: Safety is a top priority when working at heights, and electric scissor lifts offer various safety features. Guardrails, non-slip platforms, and emergency lowering mechanisms ensure the well-being of operators. Additionally, they are less prone to tip-overs compared to some other aerial work platforms.

Simple Operation: Operating an 10m electric scissor lift is relatively straightforward, and training can be completed quickly. This ease of use allows for increased efficiency in various work settings.

Various Models: Electric scissor lifts come in various models, with different platform sizes, weight capacities, and working heights. This means they can cater to a wide range of applications, from ceiling maintenance in warehouses to outdoor tree trimming.

Applications in Various Industries

Electric scissor lifts have found their way into multiple industries, each benefiting from their unique capabilities.

Construction: In the construction industry, electric scissor lifts are essential for tasks like installing ceiling fixtures, painting, and structural inspections. Their stability and ease of movement make them ideal for navigating busy construction sites.

Related links:How much does a plastic bottle cost?

Are ozone generators the best water treatment solution for swimming pools?

Ultimate Guide to Metal Filter: Benefits, Types & Maintenance Tips

Best compressor rifle for B2B purchasing purposes?

What are the top maintenance tips for 20 m Mobile Scissor Lifts?

Can you rebuild a final drive?

Exploring the Various Types of Scaffolding

Warehousing: In large warehouses, electric scissor lifts are used to reach high storage shelves, making them a valuable tool for inventory management and restocking.

Maintenance and Repair: Electric scissor lifts are used in maintenance and repair work across various sectors, including commercial and residential buildings, factories, and equipment servicing. They provide easy access to elevated areas without the need for ladders or scaffolding.

Event Management: Hered Electric scissor lifts are often used in the event management industry for setting up stages, lighting, and decorations at concerts, fairs, and conventions. Their quiet operation is a significant advantage in these scenarios.

Safety Precautions and Best Practices

While electric scissor lifts are generally safe and user-friendly, it's crucial to follow safety guidelines:

Training: Ensure that operators are adequately trained in the safe use of electric scissor lifts, including understanding the machine's controls, safety features, and weight capacity.

Maintenance: Regular maintenance and inspections are vital to ensure the machine is in optimal working condition.

Proper Ground Conditions: Always set up the lift on stable, level ground to prevent tip-overs.

Weight Limit: Do not exceed the lift's weight capacity, including the weight of materials and personnel.

Conclusion

Electric scissor lifts have revolutionized the way we access elevated work areas, enhancing efficiency, safety, and versatility across various industries. Their ease of use, low environmental impact, and adaptability to different terrains make them a preferred choice for a wide range of applications. Whether you're in construction, maintenance, warehousing, or event management, electric scissor Aerial Work Platforms provide a secure and efficient means of reaching new heights.

Are Autonomous Robots in Warehouses Taking Over?"Is the rise of autonomous robots in warehouses a sign of increased efficiency or a threat to human jobs?

Revolutionizing Data Centers: The Future of 19 Rack Mount Chassis?

Maximize Efficiency with 2-Sides 1-Coating Line for Sale – Everything You Need to Know!

Best tips for purchasing a scrap copper shredder?

Is purchasing a vehicle radiation detection system worth it?

Top Picks: Affordable Concrete Lintels for Sale

What is the cheapest pipe?