Gasket or O-Ring: Know the Essential Difference!

Goto King Seal to know more.

Gasket or O-Ring: Know the Essential Difference!

Are you confused about the difference between a gasket and an O-ring? If so, you're not alone. These two terms are often used interchangeably, but there are distinct differences between them. In this article, we will delve into the world of gaskets and O-rings to understand their variations, applications, and how they both play crucial roles in various industries.

1. Definition and Purpose:

To begin, let's define what gaskets and O-rings are. Gaskets are mechanical seals that fill the gaps between two or more mating surfaces, preventing leaks or ingress of contaminants. They come in different shapes, sizes, and materials, such as rubber, metal, or composite materials. On the other hand, O-rings are specific types of gaskets in the form of circular rings, typically made of rubber or elastomers. They are called O-rings due to their round shape, resembling the letter 'O.'.

2. Design and Application:

Both gaskets and O-rings serve similar purposes, but their designs and applications differ. Gaskets are used in static sealing applications, where there is no relative motion between the mating surfaces. They are commonly found in industries like automotive, plumbing, aerospace, and manufacturing. O-rings, on the other hand, are predominantly used in dynamic sealing applications, where there is reciprocating or rotating motion between the mating surfaces. These applications include hydraulic systems, pneumatic systems, and fluid handling equipment.

Related links:Ultimate Guide to Maintaining Farm Machinery Bearings

Slurry Pump: The Secret Weapon for Efficiency?

Exploring the Basics of Thrust Bearings

Exploring the Benefits of Full Bore Ball Valves

When was the check valve invented?

What is Collet Chuck? Who Needs One?

1PC Ball Valve: Your Ultimate Guide to Installation and Maintenance

3. Shape and Dimensions:

Gaskets and O-rings also differ in their shapes and dimensions. Gaskets are available in various forms, including sheets, spiral wound, or custom-cut shapes to fit specific requirements. They can be circular, rectangular, or irregular in shape. O-rings, as mentioned earlier, are circular in shape with a round cross-section. Their dimensions are standardized and categorized by their inner diameter (ID), outer diameter (OD), and cross-sectional diameter (CS).

4. Sealability and Pressure:

When it comes to sealability and pressure resistance, both gaskets and O-rings have their strengths. Gaskets provide a larger sealing area due to their larger surface coverage, making them ideal for applications where a high level of compression is required. They are commonly used in flanged connections, valve covers, and cylinder head gaskets. O-rings, on the other hand, rely on their round shape and elasticity to create a tight seal. Their sealing effectiveness is enhanced by being squeezed between two mating surfaces. O-ring seals are commonly found in hydraulic and pneumatic systems, where pressure resistance is crucial.

In conclusion, while gaskets and O-rings share the common goal of sealing gaps and preventing leaks, they differ in design, shape, application, and sealing mechanisms. Understanding these differences is essential for selecting the right sealing solution for specific industrial needs. Gaskets are versatile and widely used in static sealing applications, while O-rings excel in dynamic sealing scenarios. By considering factors such as pressure, motion, and mating surfaces, engineers and professionals can make informed decisions when choosing between gaskets and O-rings.

So, next time you encounter the terms gasket and O-ring, remember their distinctions and the critical role each one plays. Whether it's providing a reliable seal for a machinery component or preventing fluid leaks in complex systems, gaskets and O-rings ensure the integrity and efficiency of countless industries worldwide.

Want more information on floating seal? Feel free to contact us.

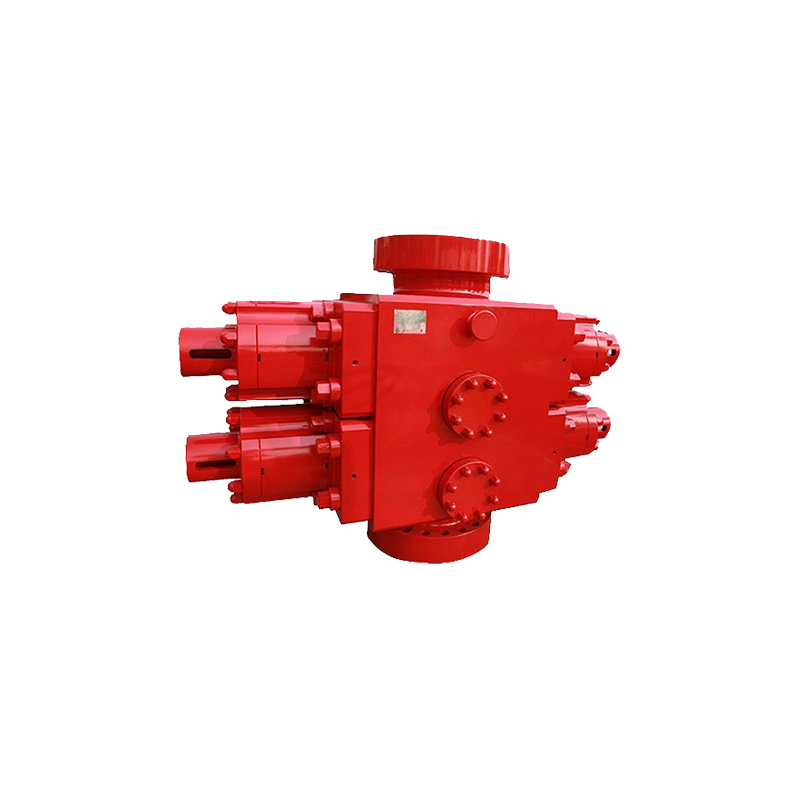

Related links:What equipment is used in drilling?

Modernize your plumbing with the full port ball valves – is it time for an upgrade?

Exploring Top Drilling Equipment Options in USA

The Ultimate Guide to Oil Country Tubular Goods: Everything You Need to Know!

Top 8 Wafer Check Valve Benefits and Features Explained!

Unlocking the Benefits of Split Rotary Tables: Your Go-To Guide!

The Ultimate Guide for Choosing Industrial Ball Valves: Which One Should You Buy?