How do you make a successful sticker?

https://www.tangyuanprint.com/custom-service.html

Let's be honest, building a custom sticker business is difficult and there is a lot of competition. However, it’s not impossible to succeed. Customers are more supportive of small businesses than ever before, and eCommerce platforms make it easier than ever to reach a worldwide audience. Forget about expensive brick-and-mortar locations — the best place to have a sticker business is online! A couple of sticker ideas won't make you wealthy, but if you have a vision, a business strategy, and a strong work ethic, you may earn a reasonable living over time.

Here are some tips and tricks on how to create your own stickers and start and run a custom sticker business.

How to Make Stickers on Your Own

Step 1: Choose your sticker paper.

To make stickers on your own, you will need printable vinyl sticker paper. You can buy it at brick-and-mortar craft stores or order online. Depending on the size of the pack and the brand, printable vinyl paper can cost anywhere from $5 to $15.

Step 2: Select a vinyl laminate.

A laminate layer applied over printable vinyl paper will make it weatherproof and extend the life of your stickers. A pack of 20 laminating sheets costs around $15.

Related links:Advantages of Flip Top Caps with Silicone Valves

Advantages and Applications of Sticky Sublimation Paper

How do you know if a plastic bucket is food grade?

How can I ensure the glass bottles I purchase meet quality standards and regulations?

How does the design and material of snack pouches ensure the freshness and shelf life of the snacks?

Non Wet Strength Metallized Paper: Unveiling the Future of Packaging

How to Maintain a Barcode Printer: A Comprehensive Guide

Step 3: Get a printer.

Unless you already have an inkjet printer, you will have to buy one. To make higher-quality stickers, you need a higher-quality printer as well. You'll want to invest in a long-lasting, dependable printer. Inkjet printers cost between $100 and $400.

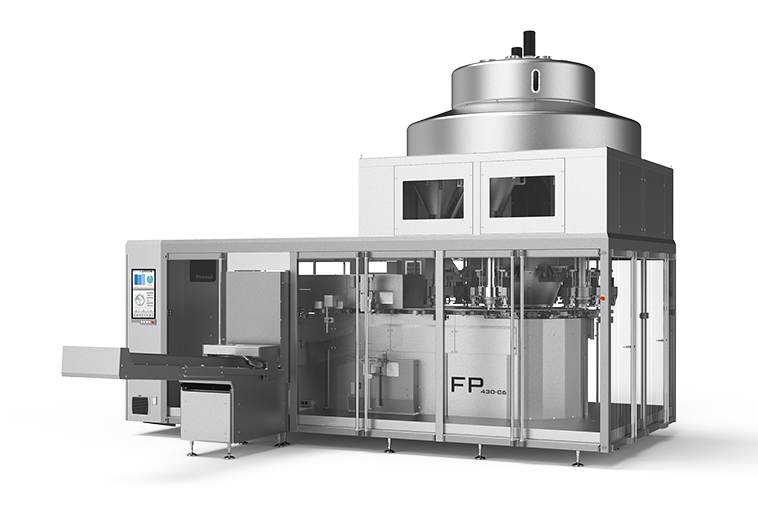

Step 4: Get a vinyl cutting machine.

You can cut vinyl using a pair of scissors or a craft knife, however, this will take some time and effort. A vinyl cutter will save you both while also helping you to achieve precise cuts. Vinyl cutters cost between $250 and $400. The Circuit and Silhouette brands are the most popular vinyl cutters among sticker makers.

Vinyl cutters can only cut vector graphics. Instead of little squares or dots called pixels, vector graphics are made of straight and curved paths with start and endpoints. These paths are based on mathematical formulae and control how the blade goes through the vinyl.

Step 5: Make stickers.

After you've finished designing stickers, print them on a piece of printable vinyl using your inkjet printer. Allow time for the ink to dry before applying the laminate layer. Cut your stickers either by hand or with a cutting machine. If you use a vinyl cutter, you will have to weed your design, i.e., remove the negative parts of it by hand.

The Magic of Spirit Glass Bottles: Enhancing the Drinking Experience

Features and Advantages of Flip Top Bottle Cap

what is cell culture

Unveiling the Elegance: Spirit Glass Bottles for Discerning Connoisseurs

Exploring LPG Cylinder Regulations: Compliance and Safety Standards

What is metallic paper?

Unveiling the Ultimate Convenience: The Flip Top Bottle Cap