How much does it cost to build a semiconductor foundry?

For more information, please visit Abu.

The world of technology is constantly advancing, with innovations that shape our everyday lives. Behind every electronic device lies the intricate world of semiconductor manufacturing. Have you ever wondered what it takes to build a semiconductor foundry? Today, we delve deep into the complex realms of costs associated with establishing a state-of-the-art semiconductor fabrication facility.

In this blog, we will explore the key elements that determine the expenses involved in constructing a semiconductor foundry. Additionally, we will shed light on some of the current industry trends and touch upon the state of the art of silicon chip manufacturing. So, let's embark on this captivating journey!

Understanding the Semiconductor Foundry Landscape:

A semiconductor foundry is a facility dedicated to the mass production of integrated circuits (ICs). These ICs form the backbone of countless electronic devices encompassing mobile phones, televisions, computers, and more. Building a semiconductor foundry is a highly complex and capital-intensive endeavor. While the actual cost can vary depending on various factors, estimates suggest that constructing a semiconductor foundry can range from several billion to tens of billions of dollars.

Factors Influencing the Cost:

1. Cleanroom Facilities: The heart of a semiconductor foundry lies in its cleanroom facilities. These meticulously controlled environments ensure the utmost purity during the manufacturing process. Creating the perfect balance of temperature, humidity, and the removal of particles demands significant investment. Advanced air filtration systems, specialized lighting, and special flooring are required, constituting a substantial portion of the overall cost.

2. Equipment and Machinery: Semiconductor fabrication necessitates cutting-edge equipment and machinery. The design and fabrication of complex semiconductor devices require advanced lithography machines, etching equipment, chemical processing tools, and more. Investing in these high-tech instruments and continuously upgrading them is crucial for staying competitive in the ever-evolving semiconductor industry.

3. R&D and Intellectual Property: Developing cutting-edge technologies heavily relies on extensive research and development efforts. Establishing a culture of innovation, attracting top talent, and protecting intellectual property are significant investments for any semiconductor foundry. From new materials and processes to novel chip architectures, such R&D endeavors contribute to both initial expenses and sustained operational costs.

4. Workforce and Expertise: Highly skilled engineers and technicians are fundamental to a semiconductor foundry's success. Building a strong workforce with diverse expertise requires substantial investment, including recruitment and training costs. Moreover, the semiconductor industry thrives on collaborations and partnerships. Therefore, fostering an environment conducive to collaboration with academia, research institutions, and industry players forms another layer of expense.

Related links:What are sanitary diaphragm pumps and how do they work?

Which industries rely on slurry pumps for efficient handling of abrasive fluids?

Common Types of Gate Valves

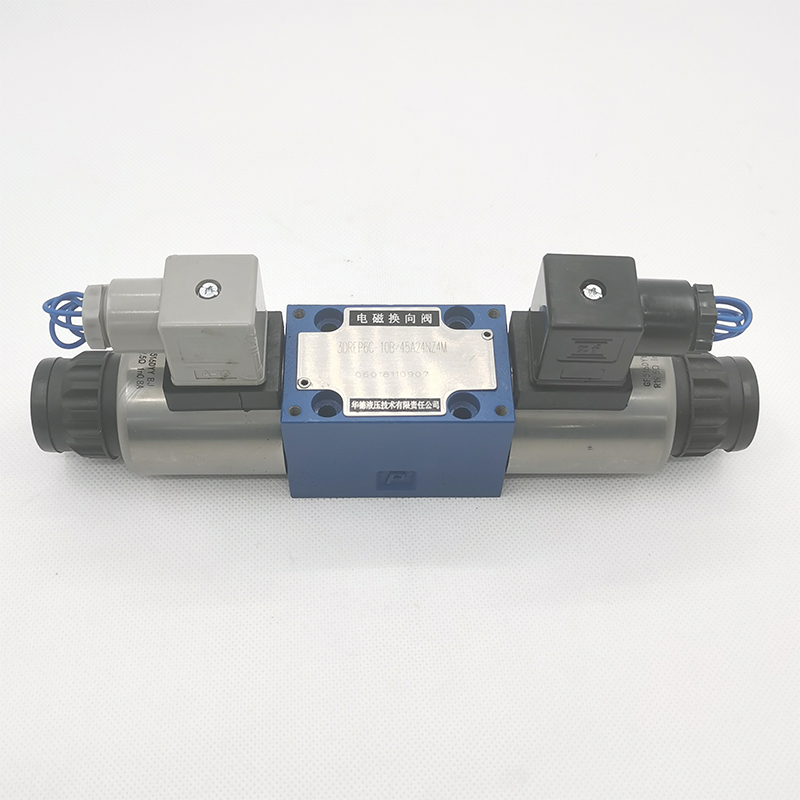

What is hydraulic directional control valve?

Natural Gas Y Strainer: Ensuring Optimal Gas Flow and Efficiency

What is API 6D ball valve?

Hydraulic Rubber Seal: Ensuring Efficiency and Reliability in Hydraulic Systems

Industry Trends and Cost Optimization:

Over the years, advancements in technology and economic factors have influenced the semiconductor foundry landscape. The industry is witnessing a trend towards consolidation, with larger companies acquiring smaller foundries to further expand their manufacturing capabilities. This consolidation helps optimize costs by streamlining production, pooling resources, and consolidating research efforts.

However, one of the most significant trends today is the emergence of fabless companies. Fabless semiconductor companies outsource the actual manufacturing process to specialized foundries, enabling them to focus on chip design and innovation. This trend has significantly reduced the barrier of entry into the semiconductor market by eliminating the need for costly foundry construction.

The State of the Art:

As technologies continue to evolve, semiconductor manufacturing is also on the brink of dramatic transformations. Advanced processes such as extreme ultraviolet (EUV) lithography, 3D integration, and the transition to larger silicon wafers are becoming mainstream, enabling higher transistor densities and improved performance.

These advancements, while driving up research and development costs, ultimately yield more cost-efficient manufacturing processes. As economies of scale improve, the costs per chip decrease, making semiconductor foundries more economically viable and sustainable in the long run.

Conclusion:

Building a semiconductor foundry is no small undertaking. The costs associated with establishing such a facility are substantial due to the complexity of the manufacturing process, cutting-edge technologies involved, and the need for highly skilled personnel. As the industry progresses, consolidation and fabless models are emerging as viable solutions to mitigate costs.

With the growing demand for electronic devices and the relentless pursuit of technological innovation, the semiconductor foundry landscape continues to evolve rapidly. It is an industry where expertise, creativity, and trustworthiness are paramount to ensure the successful construction and operation of these advanced manufacturing facilities.

For more information, please visit our website.

If you are looking for more details, kindly visit lost wax casting water pump impeller.

Related links:How does a Filter Press Feed Pump work?

What is the difference between rigid and flexible flange coupling?

What is the difference between a slurry pump and a water pump?

Are Kubota diesel engines good?

Advantages of Triplex Mud Pumps

The Benefits of Investment Casting

What is a sealing gasket and its purpose?