How to choose suitable slurry pump?

What is Slurry Pump?

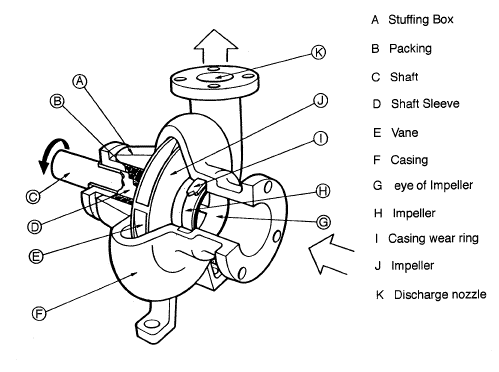

Slurry pump refers to a machine that converts electrical energy into kinetic energy and potential energy by increasing the energy of the solid & liquid mixed medium, through the action of centrifugal force (rotation of the pump impeller). The main characteristics of the slurry pump are simple structure, small size, convenient and fast installation, and long service life. It is not necessary to install filters and pumps for operation without irrigation and water diversion. When conveying the slurry containing solid particles, the slurry will not block the pipeline or nozzle and affect the operation of the machine. When transporting chemical liquids, the slurry will not react with metals to corrode them. The slurry pump can be used to transport any form of liquid.

The Application of Slurry Pump

The slurry pump can be widely used in mining, electric power, metallurgy, coal, environmental protection and other industries to transport slurry containing abrasive solid particles. Such as slurry pumping in metallurgical concentrators, hydraulic ash removal in thermal power plants, coal slurry and heavy medium pumping in coal washing plants, dredging of river channel. In the chemical industry, it is also possible to transport some corrosive slurries containing crystals. The slurry pump used for selecting sand in seawater and dredging sand in river channels,so it is called sand pump or dredging pump. There are also mud pumps, impurity pumps, dredging pumps, sludge removal pumps, etc., which are all within the scope of application of slurry pumps. Although called name differently, they are collectively referred to as slurry pumps.

How to choose suitable slurry pump?

The reasonable selection of slurry pumps should start with the following two points: suction conditions and output conditions.

Suction conditions: Choosing appropriate suction conditions is the key to ensuring the normal operation of the pump. When pumping slurry, the pressure at any point in the system must never be lower than the liquid vaporization pressure at that temperature. Therefore, it is necessary to ensure that there is sufficient pressure at the pump inlet to enable the slurry to overcome pressure losses at the inlet, suction pipe, and impeller inlet, and to continuously feed the slurry into the impeller.

Related links:

Modernize your plumbing with the full port ball valves – is it time for an upgrade?

Exploring Top Drilling Equipment Options in USA

The Ultimate Guide to Oil Country Tubular Goods: Everything You Need to Know!

Top 8 Wafer Check Valve Benefits and Features Explained!

Unlocking the Benefits of Split Rotary Tables: Your Go-To Guide!

The Ultimate Guide for Choosing Industrial Ball Valves: Which One Should You Buy?

Weir Type Diaphragm Valve: A Reliable Solution for Flow Control

Output conditions: The working point of the pump is near the efficiency point. The specific requirements are: the allowable working range of the slurry pump is between 0.6 and 1.2 of the design flow rate (p), and the reasonable working range value is recommended to be between 0.7 and 1.1 p. A good operating working point is the design point or near the design point (generally the middle of the three sets of data for the product sample), and the smaller the deviation from the design point, the better, and work near the left of the efficiency point.

Shijiazhuang Ruite Pump Co., Ltd.

Excellent technology, Top slurry pump engineers.

Stable and reliable technology.

The most reliable quality, most professional technology, most thoughtful service .

Very big slurry pumps manufacturer in China, have independent slurry pump production lines.

Related links:Plug Valves: Versatile Flow Control Solutions

High-Pressure Quick Connect Nozzle Spray Gun: The Ultimate Tool for Efficient Cleaning

The Essential Guide to Overhead Conveyor Bearings: Everything You Need to Know

The Benefits of Using Activated Carbon Filters in Your Home

Drum Gear Coupling: The Backbone of Efficient Power Transmission

Importance of Sucker Rod BOPs

Selecting the Right Slurry Pump or Sand Dredge Pump