What are the key components in a lithium battery module pack assembly line?

In the ever-evolving landscape of technology and energy storage, the demand for lithium batteries has surged to unprecedented heights. These high-energy-density powerhouses have become essential components in a wide array of applications, from smartphones to electric vehicles. As a result, the production of lithium battery module pack assembly lines has become a crucial facet of the battery industry. In this comprehensive guide, we will delve into the key components of a lithium battery module pack assembly line, shedding light on the intricate process that underpins this vital sector.

Before we delve into the components that make up a lithium battery module pack assembly line, it's important to understand the process itself. These assembly lines are the lifeblood of the lithium battery industry, responsible for crafting battery modules that power our modern world.

Lithium battery module pack assembly lines are highly specialized and meticulously designed systems. They consist of various components and workstations that contribute to the seamless assembly of lithium battery modules. These modules serve as the heart of various electronic devices and electric vehicles, making their production critical for many industries.

Key Components of a Lithium Battery Module Pack Assembly Line

Electrode Manufacturing Station

At the core of the assembly line is the electrode manufacturing station. This is where the electrodes, crucial components of lithium batteries, are produced. The station comprises a series of intricate machines and processes that create anodes and cathodes, the key elements of the battery. Precision is paramount here, as even the slightest variation in electrode quality can impact the overall performance and longevity of the battery.

Electrode Coating Machines

These machines play a pivotal role in the lithium battery assembly process. They apply a thin, uniform coating of active materials onto the electrode substrate, ensuring the efficient transfer of ions and electrons during the battery's operation. The coating process requires a controlled environment to maintain consistency and enhance the battery's performance.

Electrolyte Filling and Sealing

The electrolyte filling and sealing station is where the battery's electrolyte, a conductive solution, is injected into the cell. It is then securely sealed to prevent leakage and contamination. This step demands precision to guarantee the safety and reliability of the battery. A small error during this stage can have significant consequences.

Related links:What is the advantage of telescopic boom lift?

How long does ozone treatment for car take?

What does a bucking unit do?

How Does a Mobile Asphalt Plant Work?

The Differences Between Barrel and Rack Plating

The Benefits of Using Blow Molding Machines

What is the difference between a boom lift and a spider lift?

Formation Process

The formation process is a crucial step where the battery undergoes its first charge and discharge cycles. This helps stabilize the battery's performance and ensure it meets the required specifications. This station usually consists of various chambers and equipment to control temperature, humidity, and voltage.

Cell Stacking and Encapsulation

In this step, individual cells are stacked together to create a module. The cells are separated by layers of insulation and aligned precisely to maximize energy density. This process also includes the encapsulation of the module, sealing it in a protective casing to ensure safety and durability.

Quality Control and Testing

Quality control is paramount in a Lithium Battery Production Line. This stage involves rigorous testing and inspections to detect any defects or irregularities in the battery modules. Any substandard components are rejected, ensuring that only high-quality batteries make it to the market.

Battery Management System (BMS) Integration

The BMS is responsible for monitoring and controlling the battery's operation, ensuring safety and optimal performance. It plays a vital role in protecting the battery from overcharging, overheating, and other potential issues. Integrating the BMS is a critical step in the assembly process.

Packaging and Shipping

Once the battery modules pass all quality checks and integrate the BMS, they are packaged and prepared for shipping. This involves placing the modules in protective packaging and labeling them for easy identification and handling.

As technology continues to advance, so too will the lithium battery module pack assembly process. Research and development efforts are ongoing to enhance battery performance, energy density, and safety. Innovations such as solid-state batteries and improved recycling methods are poised to revolutionize the industry, making these assembly lines even more critical in the future.

In conclusion, the production of lithium battery modules is a complex and highly specialized process. The key components discussed in this article are vital to ensuring the quality and reliability of lithium batteries, which power countless devices and vehicles worldwide. As technology evolves, so too will these assembly lines, pushing the boundaries of energy storage and sustainability.

Related links:What is a cableway used for?

How to Choose a Commercial Well Drilling Rig

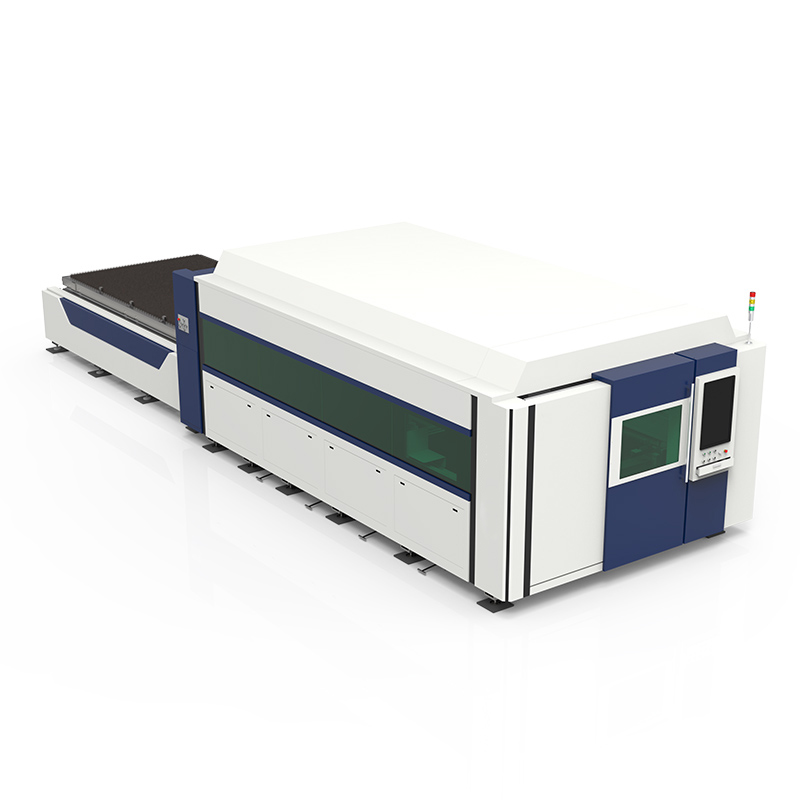

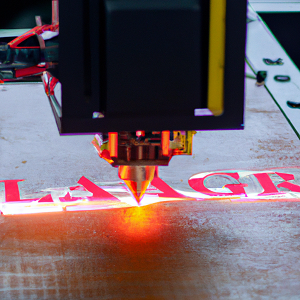

What is a fiber laser cutting machine used for?

What is the Difference Between a Condenser and a Cooling Tower?

What is a conveyor roller used for?

Do you really need a welding table?

Can I Use an Almond Grinder for Other Nuts? Exploring the Versatility of Nut Grinders