PET VS PETG, What's the difference?

When it comes to choosing materials for various applications, the distinction between PET (Polyethylene Terephthalate) and PETG (Glycol-Modified Polyethylene Terephthalate) is often a point of confusion. In this exploration, we will unravel the differences between PET and PETG, shedding light on their unique properties and applications.

Understanding the Basics: PET

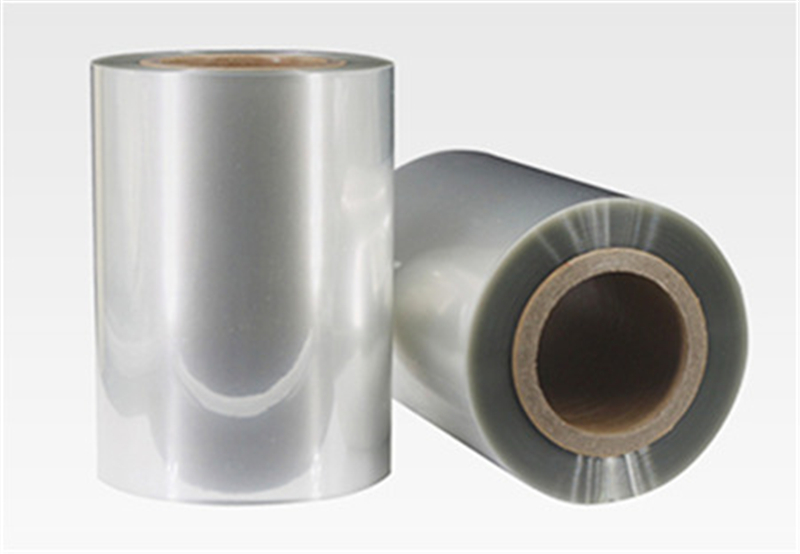

PET, or Polyethylene Terephthalate, is a widely used thermoplastic polymer known for its clarity, strength, and versatility. Commonly recognized as the material used in beverage bottles, PET has become a staple in various industries due to its transparency, lightweight nature, and recyclability.

The Evolution: PETG

PETG, or Glycol-Modified Polyethylene Terephthalate, is an enhanced version of PET. The modification involves the inclusion of glycol during the polymerization process, leading to a material with improved chemical resistance, impact resistance, and ease of processing. This evolution makes PETG stand out in applications where the standard PET might fall short.

Clarity vs. Impact Resistance

One of the primary distinctions between PET and PETG lies in their optical properties. While PET is known for its exceptional clarity, PETG sacrifices a bit of this clarity in favor of increased impact resistance. This trade-off makes PETG a preferred choice in applications where durability and resistance to breakage are crucial, such as in packaging or protective casings.

Chemical Resistance Matters

When it comes to exposure to chemicals, PETG takes the lead. The glycol modification enhances PETG's resistance to a broader range of chemicals compared to standard PET. This property makes PETG a suitable choice for applications requiring contact with various substances, including medical devices and chemical containers.

Processing Ease: PETG's Advantage

PETG's glycol modification not only improves its performance but also makes it easier to process. PETG exhibits a lower melting point than PET, resulting in a more straightforward manufacturing process. This ease of processing contributes to its popularity in 3D printing, where PETG has become a favored filament due to its printability and strength.

Environmental Impact and Recyclability

Both PET and PETG are recyclable, aligning with the growing emphasis on sustainability. However, the glycol modification in PETG can complicate the recycling process, requiring specialized recycling facilities. As environmental considerations play an increasingly significant role in material choices, understanding the implications of recycling PETG becomes crucial.

Choosing the Right Material for the Right Application

In conclusion, the choice between PET and PETG boils down to the specific requirements of the application. PET's clarity makes it ideal for products where visual appeal is paramount, while PETG's enhanced impact resistance and chemical resilience position it as a preferred choice in applications demanding durability. As industries evolve, understanding these nuances becomes essential in making informed decisions that align with performance, processing needs, and environmental considerations. Whether it's in packaging, medical devices, or 3D printing, knowing the difference between PET and PETG ensures that you choose the right material for the right job.