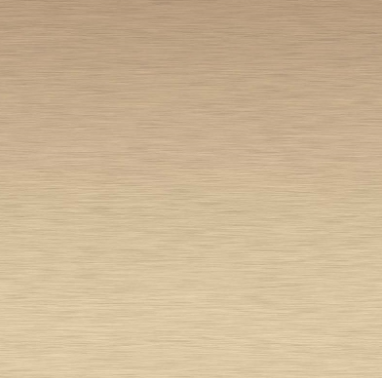

Understanding Brass Satin Stainless Steel Sheets: Properties, Applications, and Benefits

Brass satin stainless steel sheets are a unique material appreciated for their distinctive appearance and versatile properties. Defining Brass Satin Stainless Steel Sheets: Brass satin stainless steel sheets represent a composite material consisting of layers of stainless steel with a satin finish and brass, a copper-zinc alloy. This combination results in sheets with a brushed, matte surface, blending the durability of stainless steel with the decorative allure of brass.

Properties of Brass Satin Stainless Steel Sheets:

Durability: Stainless steel provides exceptional corrosion resistance, strength, and longevity, ensuring enduring performance even in challenging environments.

Aesthetic Appeal: The satin finish of stainless steel combined with the golden tint of brass creates an attractive, contemporary appearance suitable for architectural, interior design, and decorative applications.

Versatility: Available in various thicknesses, sizes, and grades, brass satin stainless steel sheets offer versatility for different fabrication methods and design requirements.

Workability: These sheets are easily machinable, allowing for straightforward cutting, forming, welding, and shaping to meet specific design specifications. This adaptability makes them ideal for architectural cladding, signage, furniture, and ornamental applications.

Applications of Brass Satin Stainless Steel Sheets:

Architectural Cladding: Widely used in architectural projects for wall cladding, facade systems, and exterior accents, brass satin stainless steel sheets enhance the visual appeal and sophistication of buildings.

Interior Design: Employed in interior design elements such as decorative panels, elevator doors, column covers, and countertops, these sheets elevate the aesthetics of commercial and residential spaces.

Furniture and Fixtures: Popular for manufacturing furniture pieces, lighting fixtures, handrails, and hardware accessories due to their durability, corrosion resistance, and contemporary appearance.

Related links:

Rethinking Corrugated Steel: The Future of Architecture?

Best tips for purchasing high-quality galvanized steel plate?

What color is a galvanized metal roof?

Galvanneal steel: Is it the ultimate sustainable choice?

Unlocking the Secrets of Hot Rolled Steel: Process, Benefits, and Applications

Revolutionizing Roofing: Creative Uses for Cold Rolled Steel?

Ultimate Guide to Ribbed Steel Rod BenefitsArt and Decor: Utilized by artists and designers for creating sculptures, artwork, signage, and decorative installations, leveraging their unique blend of aesthetics and functionality.

Benefits of Brass Satin Stainless Steel Sheets:

Aesthetic Elegance: The satin finish and warm brass tone add a touch of sophistication and refinement to architectural and interior design projects.

Durability and Longevity: Stainless steel's inherent durability combined with the corrosion resistance of brass ensures long-lasting performance, minimizing maintenance requirements.

Versatility in Design: With the ability to be machined, formed, and customized to suit specific design visions, these sheets offer flexibility and adaptability in diverse applications.

Eco-Friendly Option: Stainless steel is a sustainable material, as it is fully recyclable and contributes to environmental conservation efforts.

Brass satin stainless steel sheets represent a versatile and aesthetically appealing material choice for a wide range of architectural, interior design, and decorative applications. With their unique properties and benefits, these sheets continue to be favored by designers, architects, and manufacturers seeking to elevate their projects with a blend of style and functionality.

Revolutionizing Home Design: Color Coated Steel Coil" - How can this modern material transform homes?

Our Guide to Choosing the Best Steel Rust Protection ...

6 Benefits of Coated Steel Prepainted Coils: The Ultimate Guide!

Hot Dipped Galvanized Steel Sheet & Coil

Why steel coils are called Wire rod?

Guidelines for poured concrete over corrugated metal

What are the best uses for steel wire rod?