What is a pipe threading machine used for?

If you want to learn more, please visit our website BH.

Welcome to our comprehensive guide on pipe threading machines! In the realm of plumbing, these heavy-duty devices play a vital role, ensuring precise and efficient thread cutting on pipes. Today, we will delve into the fascinating world of pipe threading machines, exploring their uses, advantages, and the remarkable impact they have on various industries. So, buckle up as we unravel the mysteries behind these indispensable tools!

Understanding Pipe Threading Machines (150 words).

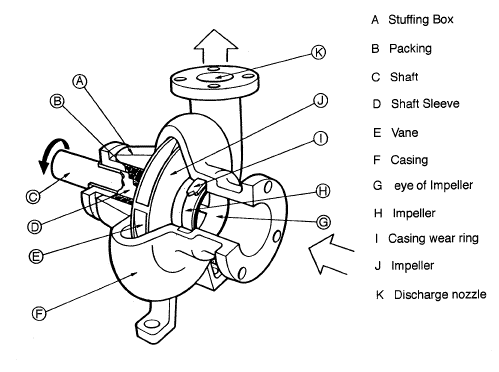

Pipe threading machines are specialized tools designed to create threads on pipes, enabling the easy attachment of fittings, valves, and connectors. These machines possess incredible capabilities that save both time and effort, making them indispensable in the plumbing industry and beyond.

The main function of a pipe threading machine is to cut precise external threads onto the outer surface of pipes. By doing so, it allows for the secure attachment of pipe fittings, ensuring leak-proof connections in various applications. Pipe threads are standardized according to specific parameters, such as size, taper, and pitch, guaranteeing compatibility across different systems.

Applications and Industries (220 words).

Pipe threading machines find numerous applications across various industries, primarily in plumbing, construction, manufacturing, and oil and gas. In plumbing, these machines are extensively used for both residential and commercial applications. From water supply systems to sanitary installations, pipe threading machines ensure the seamless connection of pipes, making them an essential tool for plumbers.

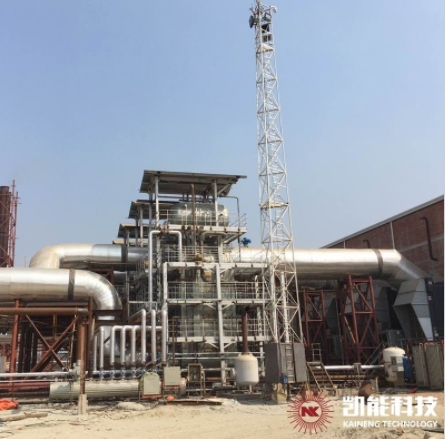

In the construction sector, pipe threading machines are critical in installing pipelines for heating, ventilation, and air conditioning (HVAC) systems. These machines create reliable and durable threads that withstand the rigorous demands of these installations.

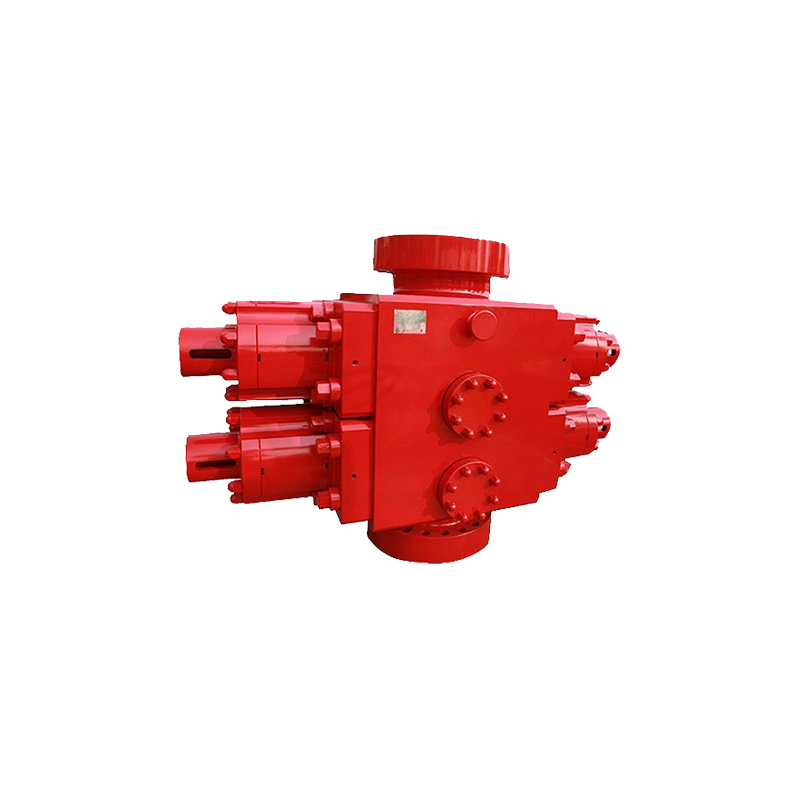

Heavy-duty industries, such as manufacturing and oil and gas, depend heavily on pipe threading machines for their piping needs. Manufacturing plants utilize thread cutting machines to create connections for fluid-carrying pipelines, ensuring smooth operations in their production processes. Similarly, the oil and gas industry relies on these machines for both onshore and offshore installations, guaranteeing safe and efficient transport of oil and gas through pipelines.

Related links:1PC Ball Valve: Your Ultimate Guide to Installation and Maintenance

What equipment is used in drilling?

Modernize your plumbing with the full port ball valves – is it time for an upgrade?

Exploring Top Drilling Equipment Options in USA

The Ultimate Guide to Oil Country Tubular Goods: Everything You Need to Know!

Top 8 Wafer Check Valve Benefits and Features Explained!

Unlocking the Benefits of Split Rotary Tables: Your Go-To Guide!

The Advantages of Pipe Threading Machines (180 words).

Pipe threading machines offer several advantages, making them a preferred choice for professionals in the plumbing and related industries. Firstly, these machines streamline the thread cutting process, allowing for faster completion of projects. With their precise cutting mechanisms, they ensure accuracy and eliminate the need for manual threading, saving valuable time and effort.

Moreover, pipe threading machines provide consistent and reliable thread quality, reducing the risk of leaks and malfunctions. This high level of quality control is essential in industries that deal with hazardous substances. Additionally, these machines offer flexibility in terms of pipe size and thread type, catering to a wide range of applications.

The Importance of Routine Maintenance (100 words).

To maintain the optimal performance of pipe threading machines, routine maintenance is crucial. Proper lubrication, regular cleaning, and inspection of parts should be implemented to avoid unnecessary breakdowns or inefficiencies. While pipe threading machines are robust and built to withstand heavy-duty usage, neglecting maintenance can lead to costly repairs or replacements.

Conclusion (90 words).

Pipe threading machines are indubitably the backbone of the plumbing industry. Their ability to create precise threads on pipes revolutionized the sector, enabling efficient connections and reducing the risk of leaks. From plumbing to construction and manufacturing to oil and gas, these machines continue to play an integral role in various industries. By understanding their functionality and advantages, professionals can harness their power to achieve seamless and reliable pipe connections, boosting productivity and ensuring customer satisfaction.

You can find more information on our web, so please take a look.

If you are looking for more details, kindly visit plastic thread protectors oilfield.

Related links:The Ultimate Guide for Choosing Industrial Ball Valves: Which One Should You Buy?

Weir Type Diaphragm Valve: A Reliable Solution for Flow Control

Plug Valves: Versatile Flow Control Solutions

High-Pressure Quick Connect Nozzle Spray Gun: The Ultimate Tool for Efficient Cleaning

The Essential Guide to Overhead Conveyor Bearings: Everything You Need to Know

The Benefits of Using Activated Carbon Filters in Your Home

Drum Gear Coupling: The Backbone of Efficient Power Transmission