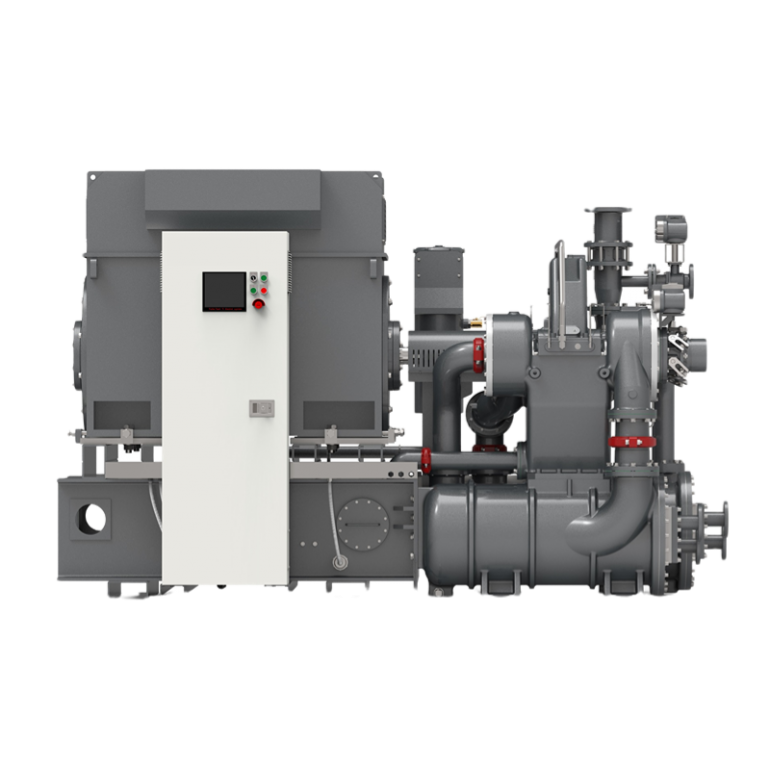

What is the principle of centrifugal compressor?

The principle of a centrifugal compressor revolves around the conversion of kinetic energy into pressure energy. Unlike positive displacement compressors, which trap and compress gas in a confined space, centrifugal compressors utilize high-speed rotating impellers to impart velocity to the gas, which is then converted into pressure as it passes through a diffuser.

The process begins with the rotation of the impeller within the compressor housing. As the impeller spins, it draws gas into the center of the compressor and accelerates it outward along the impeller blades. This acceleration increases the velocity of the gas, thereby imparting kinetic energy to it. The high-speed gas then enters a diffuser, where its velocity is gradually reduced, and its kinetic energy is converted into pressure energy. The diffuser's expanding passage allows the gas to slow down while increasing in pressure, ultimately discharging it from the compressor at the desired pressure level.

Which is the best Shea butter extraction machine?

4 Advice to Choose a Granola Making Machine

How to choose the best Nutrition Powder Machine?

What is a Nano Brewing System?

Magnetic Separation for Auto Shredding

What is the use of iron wire?

Top 10 Stainless Steel Screw Presses for Efficient Juice Extraction

The efficiency and performance of centrifugal compressors depend on several factors, including the design of the impeller, the speed of rotation, and the geometry of the diffuser. Manufacturers carefully engineer these components to maximize energy transfer and minimize losses, thereby optimizing the compressor's overall efficiency.

Centrifugal compressors find widespread applications in various industries, including oil and gas, petrochemical, and HVAC (heating, ventilation, and air conditioning). Their ability to handle large volumes of gas at relatively high flow rates makes them well-suited for applications where continuous and reliable compression is required. Additionally, centrifugal compressors are known for their smooth and vibration-free operation, making them ideal for installations where noise and vibration are critical considerations.

In summary, the principle of centrifugal compressor operation involves the conversion of kinetic energy into pressure energy through the use of high-speed rotating impellers and a diffuser. This process allows centrifugal compressors to efficiently compress gas while minimizing energy losses. With their versatility, reliability, and low maintenance requirements, centrifugal compressors play a vital role in various industrial and commercial applications, contributing to the efficient operation of processes and systems worldwide.

Ultimate Guide to Setting Up Your Own Cooking Oil Press Line

Why homemade dog biscuit machines are essential?

Which 100TPD-150TPD Flour Milling Machine is Best for Your Business?

13s4p BMS connection sequence/steps

The Ultimate Guide to Commercial Nut Roasting

Key Questions to Ask When Ordering Granola Bar Cutting Machine

4 Tips for Selecting a Wheat Flour Milling Plant Service