Which Innovations Will Revolutionize Heavy Steel Structure Buildings?

If you want to learn more, please visit our website HERBERT.

Heavy steel structure buildings have long been the backbone of architecture and construction, providing unmatched strength, durability, and versatility. However, in an era driven by technological advancements and sustainability concerns, the need to revolutionize these structures has become more pressing. Fortunately, breakthrough innovations are on the horizon, set to transform the way we conceive, design, and construct heavy steel buildings. In this blog, we will explore some key innovations that promise to reshape the industry, accelerating progress towards more efficient, eco-friendly, and awe-inspiring structures.

1. Cutting-Edge Materials:

One major avenue of innovation lies in the development of advanced materials. For instance, high-strength and lightweight alloys are being engineered to replace traditional steel, enhancing structural strength while reducing the overall weight. Moreover, self-healing materials, such as nanomaterial-infused concrete, are being developed to repair cracks and enhance durability, thereby increasing the lifespan of heavy steel structure buildings.

2. 3D Printing Revolution:

The advent of 3D printing technology has disrupted many industries, and heavy steel structure building is no exception. Additive manufacturing techniques make it possible to construct complex geometries with unprecedented precision and speed. By 3D printing intricate building components onsite, costs and logistical challenges associated with transporting large-scale steel structures can be significantly reduced. This innovation enables more efficient use of materials, reduced waste, and opens doors for endless possibilities in architectural design.

3. Sustainable Solutions:

In an era where sustainability is of paramount importance, innovative approaches to reducing the carbon footprint associated with heavy steel structures are being explored. One such approach is the integration of renewable energy sources within building structures. Imagine a heavy steel building with integrated solar panels, wind turbines, or even piezoelectric systems that generate energy from building vibrations – the potential for eco-friendly power generation is vast. Additionally, incorporating adaptive shading systems, intelligent energy management systems, and natural ventilation techniques can further enhance sustainable practices within heavy steel structure buildings.

Related links:How do you clean a stainless steel teppanyaki plate?

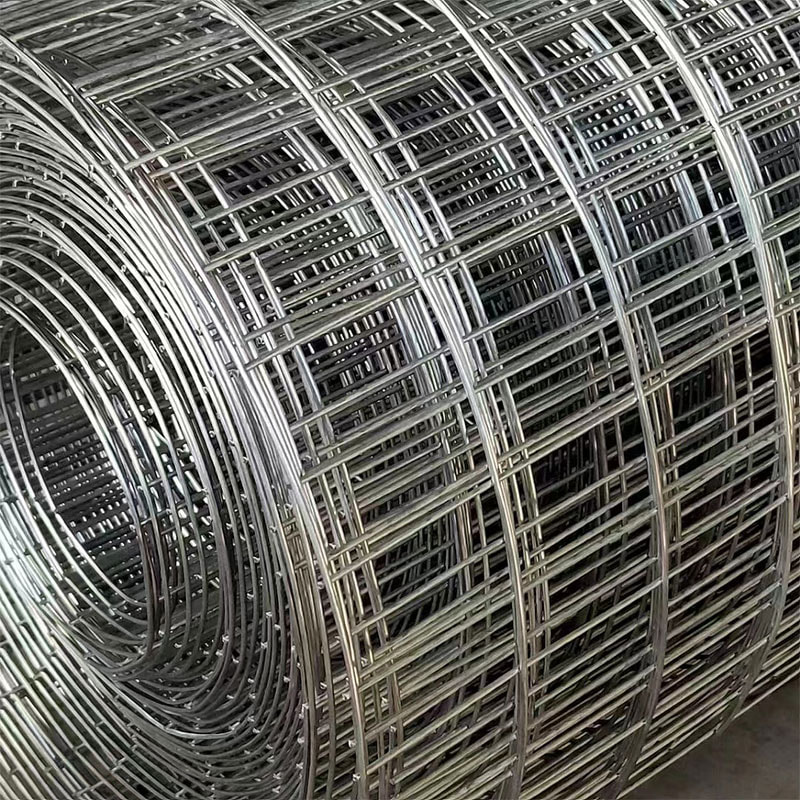

What do you use galvanized wire mesh for?

What are PC wires made of?

What is a lost head nail?

What is Cold Rolled Stainless Steel?

What is the purpose of the finned tube?

Unveiling the Advantages of Choosing Aluminum Expanded Metal

4. Robotics and Automation:

Harnessing the power of robotics and automation is another area that is poised to revolutionize the construction of heavy steel structures. By utilizing advanced robotics, tasks such as welding, cutting, and assembly can be completed with greater precision, efficiency, and speed. Automation reduces the risk of human error and enhances worker safety. Additionally, advanced drones can be leveraged to conduct on-site inspections, collecting real-time data for analysis and ensuring adherence to safety standards.

5. Building Information Modeling (BIM):

Building Information Modeling, or BIM, is another innovation that holds immense potential for the heavy steel structure building industry. BIM enables architects, engineers, and constructors to create virtual 3D models of buildings, consolidating data from design, construction, and maintenance phases. This technique facilitates collaborative decision-making, streamlines processes, improves accuracy, and reduces costs. BIM also allows for real-time simulations and analysis, ensuring optimal steel structure designs and enhanced construction timelines.

Conclusion:

The future of heavy steel structure buildings is brimming with tremendous potential due to the remarkable innovations shaping the field. Incorporating advanced materials, embracing 3D printing, prioritizing sustainability, utilizing robotics and automation, and leveraging BIM are just some of the ways in which heavy steel structures are being revolutionized. These innovations hold the key to more resource-efficient, environmentally friendly, and awe-inspiring buildings that can meet the demands of a rapidly evolving world. As the boundaries of creativity and technological capabilities continue to be pushed, heavy steel structure buildings are set to evolve into marvels of strength, utility, and sustainability.

Please visit our website for more information on this topic.

For more Space Frame Truss Power Plantinformation, please contact us. We will provide professional answers.

Related links:Unlocking the Potential of Aluminum Alloy Element Tablets

What is Razor Blade Wire?

Advantages of Cold Rolled Steel Tubes for Making Chairs

Is cordierite better than stone?

What are SmCo magnets used for?

Unveiling the Secrets of High Resistance Alloys: A Game-Changer in Modern Engineering!

What is brown aluminum oxide used for?